What we make

matters

Manufacturing medtech innovations

— with precision and purpose

What we make

matters

Manufacturing medtech innovations

— with precision and purpose

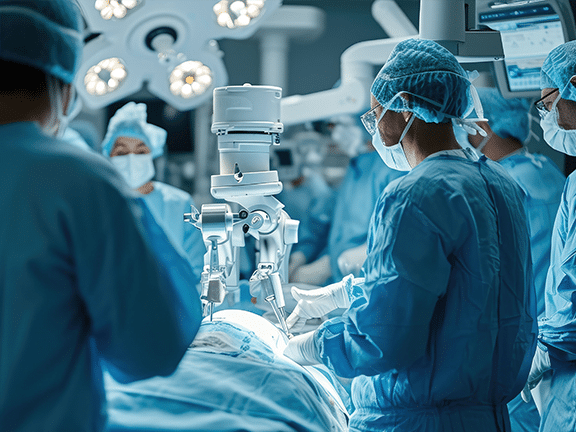

The most visionary medical device companies in the world partner with us to engineer and manufacture medtech breakthroughs designed to improve surgical outcomes for tens of millions of patients every year.

Get to Know UsDelivering customer delight

For nearly a century, we’ve been delighting customers by consistently delivering reliable performance, industry-leading quality, and collaboration you can count on to help make things better.

Retention

us as sole supplier

Making a difference in

markets that matter

We’ve invested in building our capabilities and expertise to serve some of

the most innovative and demanding markets in the world.

- Cardiovascular

- Minimally invasive surgery (MIS)

- Orthopedics

- Robotic-assisted surgery (RAS)

- Surgical technologies

Collaborating at every stage

As a trusted partner, we support you with tailored end-to-end engineering and manufacturing solutions along the entire value chain.

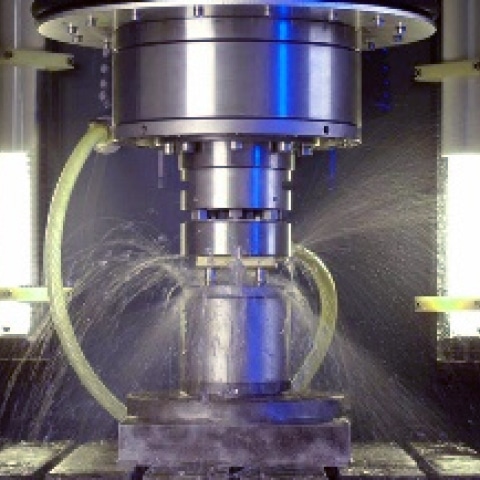

Our modern 700,000 square-foot manufacturing campus in Dayton, Ohio, combines best-in-class, in-house capabilities and world-class talent to enable high quality, short lead times, low costs, and fast problem-solving.

DFM, Engineering & Process Development

Prototyping & Tooling Development

Precision Machining & Processing

Value-Add Secondary Processing

Testing, Assembly & Packaging

Tools & teams to power

innovation

We provide more than 30 specialized, precision manufacturing, post-processing, and assembly operations—and expert teams to power them. We’re continually expanding our capabilities to meet our customers’ current and future growth needs.

Innovate & grow with a trusted partner

Whatever you design, we can engineer and manufacture it with the utmost precision. We thrive on solving the most complex manufacturing challenges.

Connect With Us

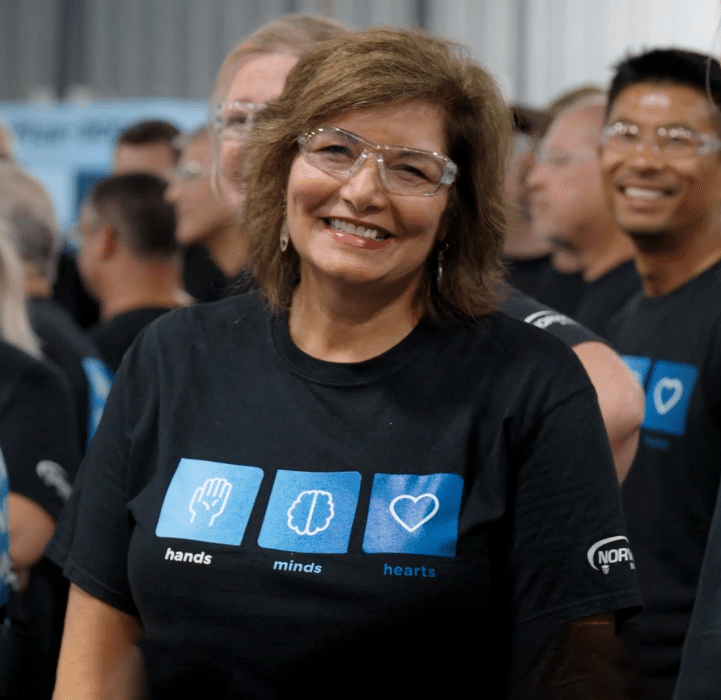

Great minds think together. Join us.

We’re growing and looking to bring world-class talent on board. Join the Norwood family of purpose-driven people dedicated to medical innovation.

Explore Jobs