At Norwood Medical, we invest 3% of our annual revenue in innovation and automation to continually drive process improvement. As part of this commitment, we’ve recently brought three new machines online that are already increasing efficiency and driving down customer costs through innovation and automation.

Multi-spindle CNC Machining

This versatile machine boosts productivity by reducing cycle time for high-volume production. With eight spindles, this one machine can do the work of eight Swiss lathe machines in one compact footprint, resulting in a whopping 50% – 80% cost saving per piece!

Makino DA300 Five-Axis Vertical Machining Center

This new machining center boosts our capabilities for low-volume, high-mix manufacturing of complex parts. Its integrated large-capacity work pallet system and tool magazine allows for untended run time of 24+ hours to maximize productivity. With high speed, high accuracy, and high reliability, this versatile machine is a wizard at fabricating nearly any part geometry.

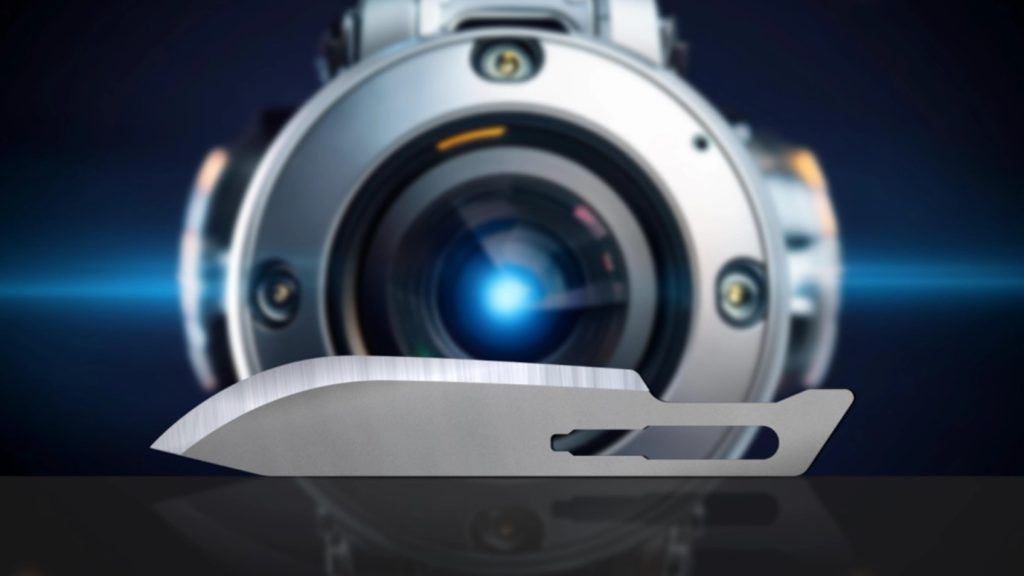

Automated AI-Based Inspection Systems

Commissioned in 2023, our custom AI-based visual inspection system is now up and running! Designed to eliminate all manual handling and manual inspection of parts, this capable system allows for automated inspection of all four views of a part. It offers increased speed and efficiency with exceptional accuracy, improving quality and reducing costs.

What’s the advantage of an AI-based inspection system? AI leverages neural networks to learn from image data and adapt to variations and complex patterns, allowing these systems to handle diverse products and subtle defects, learn from examples, and improve over time, ultimately resulting in better medical devices and improved outcomes for patients.