Serving high-

impact markets

Leading industry innovation

Serving high-

impact markets

Leading industry innovation

Our dedication to innovation, combined with a strong understanding of the intricacies of medical procedures and therapies, have earned us a reputation for creative problem solving in challenging applications and markets.

Pushing the limits of manufacturing to

improve outcomes and lives

Partnering with the leading players in the industry, we’ve invested in building our capabilities and expertise to serve markets in which we can impact patients’ lives:

Cardiovascular

Product examples:

- Cutting & piercing devices

- Tissue cutters

- Scissors

- Blades

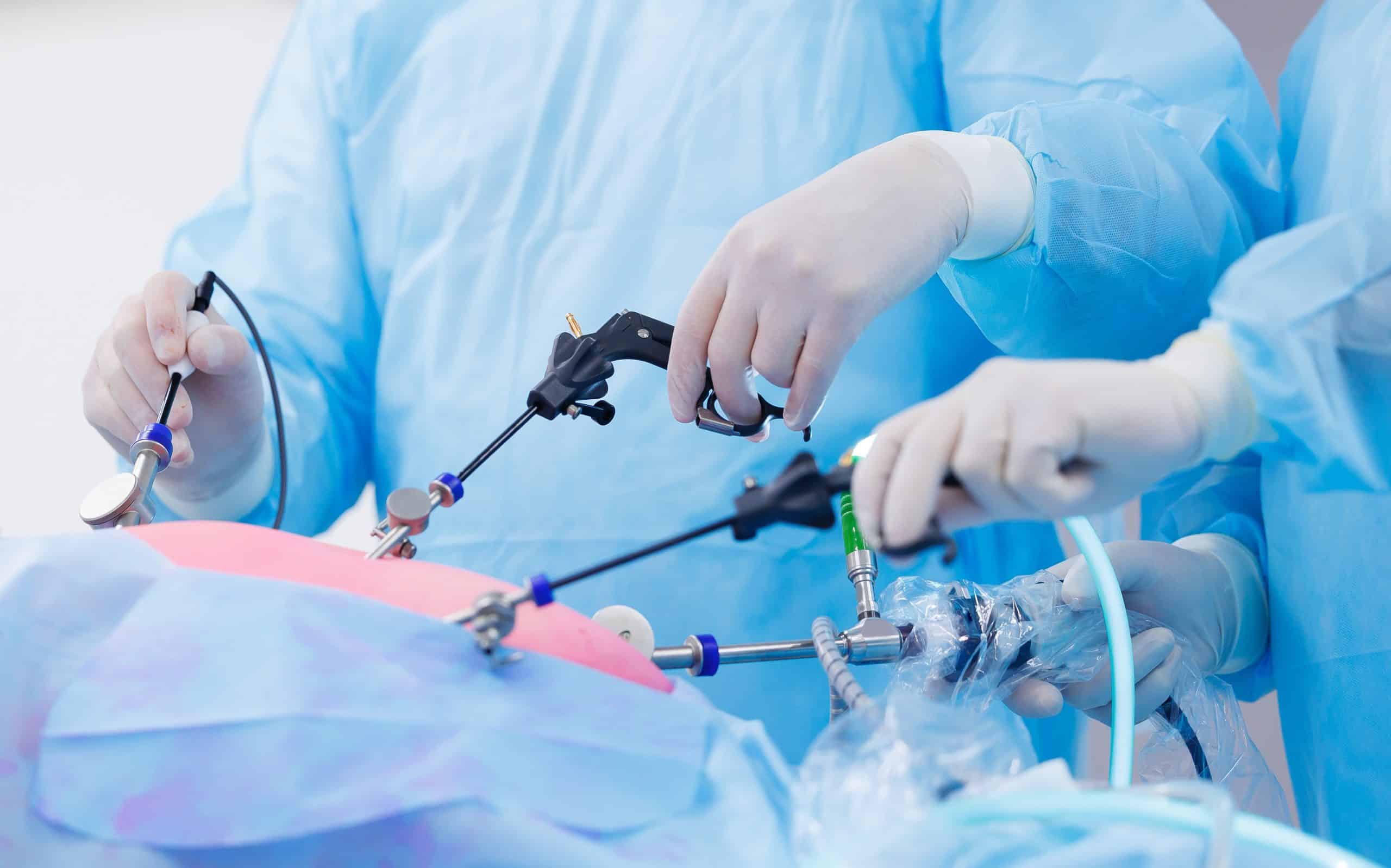

Minimally invasive surgery (MIS)

Endoscopic solutions include:

- Linear stapling systems

- Circular stapling systems

- Knives

- Energy-sealing devices

- Clip appliers

Orthopedics

Complex implants, instruments & fixation solutions for:

- Arthroscopic

- Spinal

- Trauma & extremities surgery

- Joint reconstruction

- Sports medicine

Product examples:

- Ankle clamps

- Needles

- Impaction handles

- Screws & plates

- Stems

Robotic-assisted surgery (RAS)

Trusted supplier for more than 15 years

Applications:

- Complex robotic instruments & components (reuseable & single use)

- Robotic systems & accessories

Surgical technologies

Product examples:

- RF Therapy devices

- Energy-sealing devices

- Dissection devices

- Surgical staplers

- Cannulas

Creating medical engineering breakthrough

With more than 40 years of experience, we’ve focused on developing technological capabilities, advanced engineering solutions, and manufacturing systems to consistently deliver results as a trusted partner. Learn how we leverage our core capabilities to bring our customers’ innovations to life.

Get Started