Norwood Medical’s cutting-edge AI visual inspections enhance medical device quality and improve surgical precision and outcomes for tens of millions of patients each year.

Minimally Invasive Surgery on the Rise

Globally, 310 million major surgeries are performed annually, with the USA and Europe accounting for 40 to 50 million and 20 million, respectively. As the world’s population ages and access to healthcare worldwide increases, precision and safety of surgical care have become critical global health priorities.

Minimally invasive surgery (MIS) offers patients many benefits including smaller incisions, faster recovery, reduced postoperative complications, and shorter hospital stays. Technological advancements in medical devices have improved the operability of MIS procedures, and the global demand for minimally invasive surgeries is expected to grow at a rate of 6% annually between 2023 and 2032.

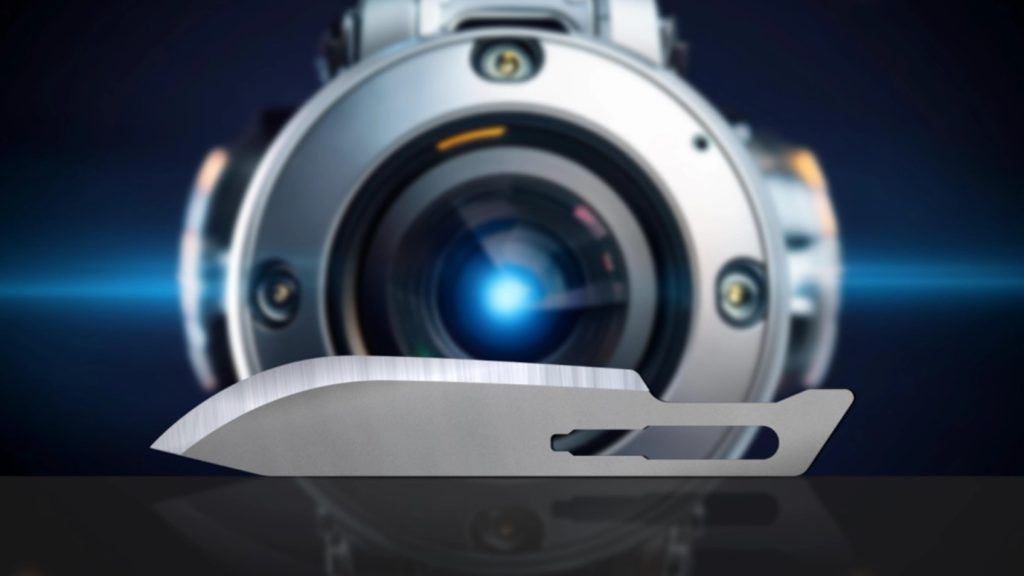

Norwood Medical makes millions of precision medical device components that are critical for minimally invasive procedures across multiple end-markets. In 2024, Norwood Medical manufactured over 6 million disposable surgical knives. For each one laser-focused quality inspection is integral for ensuring optimal patient outcomes. One of Norwood’s latest projects is the deployment of an AI-powered automated vision inspection machine for surgical blades.

Case Study: Realizing Unparalleled Precision in Surgical Knives Through AI

Traditionally, surgical blades undergo inspection using a microscope and physical examination. With an annual output of over 6 million knives, this process requires tens of millions of inspections on blades with bare eyes.

By integrating advanced AI-driven vision inspection machines, Norwood Medical achieves levels of defect detection that are unmatched in the industry. The AI-powered inspection system deployed by Norwood Medical leverages four high-resolution cameras and deep-learning models trained on 18,000+ images of surgical blades. These models can detect microscopic imperfections – edge damage, cracks, thickness variations, stains, residue, and tool marks – as tiny as the tip of a ballpoint pen.

The shift towards AI-powered automated visual inspection offers patients and customers:

- Fewer device failures during surgery thanks to reduced manual handling risks, incl. human error

- Surgical accuracy through a zero-defect mindset and consistent precision

- Enhanced recovery outcomes due to smaller and more precise incisions

- Speed and reduced costs

At Norwood Medical innovation happens through collaboration. Combining expert teams, in-house engineering, and close customer partnerships has driven rapid AI adoption and qualification on the knife production lines.

“We started as early as in 2018 and were among the first to propose the use of AI. Our customer was involved from the very beginning. They have embraced the idea and initiated the qualification process.”

– Leon Jones, VP of Controls & Automation

Takeaway: Precision That Transforms Patient Safety

Norwood Medical’s AI-driven quality inspection isn’t just about technological progress – it’s about people shaping a future where every patient benefits from safer, more effective medical devices. Their dedication to precision, partnership, and excellence is redefining surgical outcomes – proving that innovation isn’t just a promise, it’s a daily practice for those who engineer what matters most.

A culture of innovation and collaboration is deeply embedded within Norwood Medical. By continuously investing into automation, AI, and new technologies, Norwood Medical is setting new standards for patient safety in minimally invasive procedures.

If you want to know more or want to discuss an idea, get in touch with us.